Choosing the right laser cutting machine depends on several key factors tied to your industry, materials, production volume, and budget. Here’s a clear guide to help you make the best decision

1. Know Your Material Requirements

Different laser types are suited for different materials:

| Material Type | Recommended Laser |

|---|---|

| Metals (steel, aluminum, copper) | Fiber laser |

| Wood, plastics, acrylic, leather | CO₂ laser |

| Thin metals & non-metals | Hybrid or CO₂ |

| Glass, ceramics | UV laser (specialized) |

2. Understand Machine Types

- CO₂ Laser Cutters

- Ideal for non-metals (wood, leather, acrylic).

- Affordable for light industrial and craft use.

- Slower than fiber lasers for metals.

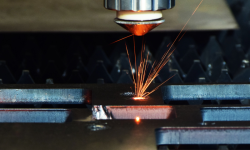

- Fiber Laser Cutters

- Best for metal cutting (steel, brass, aluminum).

- High speed, low maintenance.

- Higher initial cost but lower long-term cost.

- Nd:YAG/Nd:YVO₄ (Crystal Lasers)

- Suitable for precision cutting (medical, electronics).

- High maintenance costs.

3. Cutting Thickness & Power Needs

Match machine power (measured in watts) to your cutting needs:

| Thickness (mm) | CO₂ Laser (Watts) | Fiber Laser (Watts) |

|---|---|---|

| 1–3 mm | 40–100W | 500–1000W |

| 5–10 mm | 100–300W | 1000–3000W |

| 10+ mm | Not recommended | 3000W+ |

4. Key Features to Consider

- Work area size – Depends on your sheet sizes or project dimensions.

- Software compatibility – For CAD/CAM integration.

- Cooling system – Especially for high-power lasers.

- Automation – For high-volume industries, look for automatic loaders/unloaders.

- Service & support – Local service reduces downtime.

5. Match It to Your Industry

| Industry | Recommended Laser Type |

|---|---|

| Metal fabrication | High-power Fiber laser |

| Advertising/signage | Mid-range CO₂ laser |

| Automotive/aerospace | Fiber laser with automation |

| Medical devices | Precision Nd:YAG or Fiber |

| Crafts & prototyping | Desktop CO₂ or diode laser |

6. Budget Considerations

- Entry-level CO₂: $3,000–$10,000

- Mid-tier CO₂/Fiber: $10,000–$50,000

- Industrial Fiber Lasers: $50,000–$500,000+

Final Tips

- Start small if you’re prototyping or testing new products.

- Invest in training for your team.

- Get sample cuts from vendors before you commit.

- Check reviews & maintenance costs before purchasing.

Would you like help comparing specific models or brands?