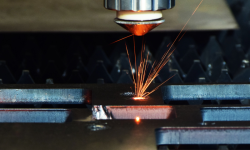

Laser machines are a long term investment for manufacturers working in metal cutting, welding, marking, engraving, and surface processing. These machines operate under high thermal load, continuous duty cycles, and strict accuracy requirements. While buyers often focus on laser power, brand, and automation features, the performance of any laser machine over time depends heavily on the quality and suitability of its spare parts.

Laser spare parts are not just replacement items. They directly affect beam quality, cutting accuracy, weld strength, marking clarity, machine uptime, and overall operating cost. Poor spare part selection can result in frequent breakdowns, inconsistent output, and expensive damage to core machine components.

This buyer’s guide is written for laser machine owners, maintenance teams, and procurement managers. It explains everything that must be understood before purchasing laser spare parts, including part categories, buying criteria, maintenance planning, and supplier evaluation, with reference to LaserCart.co standards and industry practices.

Why Choosing the Right Laser Spare Parts Matters

Laser machines rely on a precise balance of optical, mechanical, electrical, and thermal systems. Every spare part plays a role in maintaining this balance. Even a small mismatch in quality or compatibility can reduce machine efficiency and affect final product quality.

Key reasons why the right spare parts matter include:

- Maintains consistent cutting, welding, or marking accuracy across production batches

- Prevents beam distortion caused by low grade optical components

- Reduces unplanned machine downtime and production losses

- Protects expensive components such as laser sources and cutting heads

- Extends overall machine service life and reliability

- Helps control long term maintenance and replacement costs

LaserCart.co focuses on supplying machine compatible spare parts that are tested for industrial usage, continuous operation, and stable performance under demanding conditions.

Understanding the Major Categories of Laser Spare Parts

Before purchasing, machine owners should clearly understand the different categories of spare parts used in laser cutting, welding, and marking systems. Each category serves a distinct function and has different replacement cycles.

Optical Components

Optical components are among the most critical parts of any laser system. They guide, shape, and focus the laser beam from the source to the workpiece. Any defect or contamination in optics directly affects beam quality and processing results.

Common optical spare parts include:

- Collimating lenses that align and stabilize the laser beam

- Focusing lenses that determine spot size, depth, and accuracy

- Protective cover lenses that shield internal optics from dust, fumes, and spatter

High quality optics must have low absorption rates, stable coatings, and resistance to thermal stress. Poor optics can cause beam scattering, overheating, and early lens failure.

LaserCart.co optical components are manufactured using controlled materials and coating processes to support consistent beam transmission and long service life.

Consumable Parts

Consumables are parts that wear out naturally during machine operation and require regular replacement. Their condition directly impacts cut edge quality, weld cleanliness, and marking uniformity.

Common laser consumables include:

- Nozzles (single and double) that control assist gas flow and cutting precision

- Ceramic rings that provide electrical insulation and maintain nozzle alignment

- Protective windows exposed to heat, debris, and metal spatter

Using poorly manufactured consumables can lead to unstable gas flow, uneven cuts, and frequent stoppages.

LaserCart.co consumables are produced with accurate dimensions and material strength to ensure repeatable performance across replacement cycles.

Mechanical and Motion Related Spare Parts

Mechanical components support the movement, alignment, and positioning of laser heads and work tables. Any wear or misalignment in these parts reduces accuracy and increases vibration.

Key mechanical spare parts include:

- Linear guides and bearings for smooth axis movement

- Mounts, holders, and brackets used in laser heads

- Sensor holders and mechanical supports

Using compatible mechanical spare parts helps maintain positional accuracy, reduces noise, and avoids premature wear of connected components.

LaserCart.co supplies mechanical spares designed to match machine tolerances and operating loads.

Cooling and Electrical Spare Parts

Laser machines generate significant heat and require stable electrical performance. Cooling and electrical spare parts protect the system from overheating, power fluctuation, and safety risks.

Important cooling and electrical components include:

- Cooling pipes, connectors, and hoses

- Power supply modules and control units

- Sensors, cables, and electrical connectors

Failure in these parts can cause sudden machine shutdowns or long term damage to the laser source.

LaserCart.co ensures cooling and electrical spare parts meet operational safety standards and support continuous industrial use.

What Buyers Must Check Before Purchasing Laser Spare Parts

Selecting the correct spare part requires more than matching part names. Buyers should evaluate technical and operational factors carefully.

Key checks include:

- Machine model, laser source type, and cutting head compatibility

- Material quality and manufacturing consistency

- Heat resistance and wear life under actual operating conditions

- Supplier quality control and testing procedures

- Availability of technical guidance and after sales support

LaserCart.co provides clear product specifications and application guidance to help buyers make informed decisions.

Risks of Using Low Cost or Non Standard Spare Parts

While low priced spare parts may appear attractive, they often create hidden costs over time.

Common risks include:

- Inconsistent cutting, welding, or marking quality

- Higher frequency of part replacement

- Increased risk of damage to optics and laser heads

- Longer machine downtime and production delays

- Higher overall maintenance expenses

Choosing reliable spare parts reduces these risks and improves production stability.

Spare Parts Planning and Inventory Management

Proper spare parts planning helps machine owners avoid emergency downtime.

Best practices include:

- Identifying critical spare parts for each machine

- Maintaining minimum stock levels for consumables

- Scheduling regular inspection and replacement cycles

- Tracking part usage and failure patterns

LaserCart.co supports maintenance planning by offering consistent supply and commonly used spare parts for laser systems.

Why Machine Owners Choose LaserCart.co

LaserCart.co focuses on supplying laser spare parts that meet real industrial requirements rather than short term cost savings.

Reasons machine owners prefer LaserCart.co include:

- Wide range of laser cutting, welding, and marking spare parts

- Machine compatible designs for popular laser brands

- Controlled material selection and dimensional accuracy

- Consistent quality checks and product reliability

- Support for maintenance teams and procurement planning

Quality Standards and Material Considerations in Laser Spare Parts

When evaluating laser spare parts, understanding material quality and manufacturing standards is essential. Laser machines operate under extreme conditions such as high temperatures, focused energy density, and continuous motion. Spare parts must withstand these stresses without deformation or performance loss.

Important material factors to evaluate include:

- Optical grade glass purity and coating consistency

- Thermal resistance of ceramics and metal alloys

- Dimensional stability under heat and vibration

- Surface finish quality to reduce contamination and wear

LaserCart.co follows controlled material selection to ensure spare parts perform reliably across long production cycles.

Role of Spare Parts in Cutting, Welding, and Marking Quality

Laser spare parts have a direct and measurable impact on output quality across different applications.

Impact on Laser Cutting Quality

- Stable optics maintain consistent kerf width

- Proper nozzles ensure uniform gas flow

- Accurate mechanical alignment prevents edge taper

- Clean protective lenses reduce burn marks

Impact on Laser Welding Quality

- Consistent beam focus improves weld penetration

- Stable cooling parts prevent heat fluctuation

- Reliable electrical components avoid power variation

- Clean optics support smooth weld seams

Impact on Laser Marking Quality

- Precise optics improve marking clarity

- Stable motion parts ensure repeatable positioning

- Clean consumables support high contrast marking

LaserCart.co spare parts are designed to support all three applications without performance compromise.

Common Spare Part Failure Causes and How to Avoid Them

Understanding why spare parts fail helps reduce replacement frequency and downtime.

Common causes include:

- Contamination from dust, fumes, or metal spatter

- Incorrect installation or alignment

- Using non compatible spare parts

- Overheating due to poor cooling maintenance

- Delayed replacement of worn consumables

Preventive measures include:

- Regular inspection of optics and consumables

- Cleaning optical components using approved methods

- Replacing parts at recommended intervals

- Using machine compatible spare parts

Maintenance Best Practices for Longer Spare Part Life

Proper maintenance extends spare part life and improves machine reliability.

Recommended practices include:

- Daily visual inspection of nozzles and cover lenses

- Scheduled cleaning of optics and sensors

- Monitoring cooling system performance

- Checking alignment after part replacement

- Keeping maintenance records for each machine

LaserCart.co spare parts support predictable maintenance schedules and stable performance.

Procurement Guidelines for Maintenance and Purchase Teams

Maintenance and procurement teams should follow structured purchasing practices to avoid errors.

Key procurement guidelines include:

- Maintain a verified spare part list for each machine

- Standardize suppliers for consistent quality

- Avoid mixing low grade and high grade components

- Plan annual spare part budgets based on usage data

- Keep emergency spares for critical components

LaserCart.co helps procurement teams with consistent product availability and specifications.

Spare Parts Inventory Strategy for Multi Machine Facilities

Facilities operating multiple laser machines must manage spare parts inventory carefully.

Effective strategies include:

- Categorizing parts as critical, regular, or low usage

- Stocking consumables based on production volume

- Sharing common spare parts across similar machines

- Reviewing inventory usage quarterly

- Avoiding overstocking of slow moving parts

LaserCart.co supports scalable spare part supply for growing production facilities.

Supplier Evaluation Checklist for Laser Spare Parts

Choosing the right supplier is as important as selecting the right part.

Evaluation criteria include:

- Product range covering major laser applications

- Consistent quality control processes

- Technical documentation and specifications

- Industry experience and application knowledge

- Reliable delivery and after sales support

LaserCart.co meets these expectations by focusing on industrial grade spare parts and customer support.

Cost of Ownership Perspective on Laser Spare Parts

Instead of focusing only on purchase price, buyers should evaluate total cost of ownership.

Cost factors include:

- Replacement frequency

- Impact on machine uptime

- Effect on output quality and rejection rates

- Risk of damage to expensive components

Reliable spare parts reduce long term costs by improving machine stability.

Final Buying Guidance for Laser Machine Owners

A laser machine performs only as well as the spare parts supporting it. Machine owners who understand spare part categories, material quality, maintenance practices, and supplier reliability are better positioned to protect their investment.

Choosing dependable spare parts from a trusted supplier such as LaserCart.co helps maintain consistent performance, reduce downtime, and support long term manufacturing success.

For product support and technical guidance, contact at +91 8866608444 or mail at info@lasercart.co. You can also visit our website at www.Lasercart.co to know more.