Introduction to Fiber Laser Cutting

In today’s highly competitive manufacturing environment, precision, speed, and efficiency are non-negotiable. As industries evolve, the demand for technologies that can deliver high-quality output while minimizing operational costs is at an all-time high. Enter the fiber laser cutting machine – a groundbreaking tool in the realm of metal fabrication.

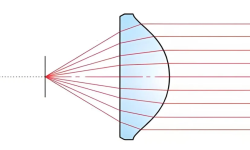

Fiber laser cutting has quickly emerged as the go-to solution for businesses seeking precision and performance. Unlike traditional cutting methods, fiber lasers use a solid-state laser beam generated through optical fibers doped with rare-earth elements. This beam is then directed onto metal surfaces, providing unmatched cutting accuracy and speed. The rise of fiber laser technology represents a significant leap forward in how we approach industrial cutting tasks, especially in sectors where detail and efficiency are critical.

How Fiber Laser Cutting Differs from CO2 and Other Types

To appreciate the revolutionary impact of fiber laser cutting machines, it’s essential to understand how they compare with other laser types, particularly CO2 lasers.

1. Light Generation and Transmission: CO2 lasers use a gas mixture (primarily carbon dioxide) excited by electrical energy to produce the laser beam, which is then reflected using mirrors to the cutting head. In contrast, fiber lasers use optical fibers to guide the laser beam directly to the cutting head, eliminating the need for mirrors and resulting in fewer alignment issues and maintenance requirements.

2. Efficiency: Fiber lasers are significantly more energy-efficient than CO2 lasers. While CO2 systems typically convert only 10% of input power into a laser beam, fiber lasers can reach efficiencies of over 40%. This leads to reduced power consumption and lower operational costs.

3. Cutting Speed and Material Compatibility: Fiber lasers excel at cutting thin to medium-thick metal sheets (especially reflective metals like aluminum, brass, and copper) at faster speeds than CO2 lasers. Their shorter wavelength allows for better absorption into metals, increasing cutting speed and quality.

4. Maintenance and Durability: The all-solid-state design of fiber lasers makes them more robust and requires less maintenance. There’s no need for gas refills, mirror replacements, or frequent alignments, making them a hassle-free solution for high-volume operations.

5. Footprint and Integration: Fiber laser systems are generally more compact and easier to integrate into automated production lines, aligning with smart manufacturing trends and Industry 4.0 practices.

Benefits: Speed, Accuracy, and Energy Efficiency

Fiber laser cutting machines bring a host of advantages that make them a preferred choice across industries:

1. Unmatched Precision: The fine laser beam allows for intricate cuts with high tolerances. This precision makes fiber lasers ideal for applications demanding complex geometries and tight dimensional control.

2. High-Speed Processing: Thanks to rapid beam delivery and optimized power use, fiber laser machines can cut through metal sheets swiftly, reducing production time significantly.

3. Energy Efficiency: With their superior power conversion rates and minimal energy wastage, fiber lasers stand out as a sustainable option for manufacturers looking to reduce their carbon footprint and utility expenses.

4. Minimal Material Waste: The accuracy of fiber laser cutting results in clean edges and reduced kerf, meaning less rework and lower material wastage.

5. Lower Operating Costs: Due to minimal consumables, reduced maintenance, and lower energy consumption, fiber laser cutting machines contribute to long-term cost savings.

6. Flexibility: Whether it’s stainless steel, mild steel, copper, brass, or aluminum, fiber lasers can handle a wide range of materials with ease, offering flexibility for different job requirements.

Applications in Various Industries

Fiber laser cutting machines are used across a broad spectrum of industries, thanks to their versatility and reliability.

1. Automotive Industry: Precision is paramount in automotive manufacturing. Fiber lasers are used for cutting car body components, gears, brackets, and other parts with tight tolerances. Their ability to handle reflective materials also makes them ideal for cutting aluminum and copper components used in electric vehicles.

2. Aerospace Sector: Aircraft components require superior precision and minimal material distortion. Fiber lasers provide clean, accurate cuts in high-strength alloys used in aerospace engineering, ensuring part integrity and safety.

3. Signage and Advertising: Fiber lasers allow for the creation of detailed signs and lettering with perfect edge quality. Their ability to handle various metals and deliver consistent output makes them ideal for both indoor and outdoor signage fabrication.

4. Electronics and Electrical Equipment: With miniaturization becoming a trend in electronics, fiber lasers support the need for precise cuts in small components and delicate materials like thin copper and aluminum sheets.

5. Medical Devices: In the medical industry, where precision is vital, fiber laser cutting is used to produce surgical instruments, implants, and other critical devices that must meet stringent quality standards.

6. Construction and Architecture: Metal frameworks, railings, decorative panels, and more – fiber laser cutting machines are used to manufacture aesthetically pleasing and structurally sound components in the building and construction sector.

7. Defense and Heavy Engineering: From armored vehicle panels to complex brackets and reinforcements, the defense sector leverages fiber laser machines for dependable and durable metal cutting solutions.

SLTL Group’s Innovations in Fiber Laser Cutting Machines

SLTL Group, a global pioneer in laser technology, has continually pushed the boundaries of what fiber laser cutting machines can achieve. Known for engineering excellence and innovation, SLTL has developed a range of cutting-edge machines that deliver superior performance, reliability, and user-centric design.

1. VECTOR Series: The VECTOR series is a standout example of SLTL’s commitment to innovation. SLTL cutting machines come equipped with automation features like auto-sheet loading/unloading, dynamic fume extraction systems, and intelligent nesting software to maximize material usage and productivity.

2. Infinity F1 : A compact yet powerful solution designed for maximum acceleration and cutting speeds, this model boasts a high-rigidity aluminum gantry, ergonomic 3D fiber laser cutting capability, and intelligent IOT-based machine monitoring.

3. Smart Manufacturing Integration: SLTL’s fiber laser machines are integrated with Industry 4.0 technologies, allowing seamless data exchange, real-time monitoring, predictive maintenance alerts, and enhanced operator control – all contributing to a smart and efficient production environment.

4. Global Reach and Customization: SLTL delivers customized laser solutions tailored to industry-specific needs. Whether it’s high-speed cutting for electronics or thick metal cutting for infrastructure, SLTL has a solution that fits.

5. Sustainability Focus: Through energy-efficient lasers and minimal waste generation, SLTL contributes to eco-friendly manufacturing practices, aligning with global sustainability goals.

6. Service and Support: SLTL offers unparalleled customer support, training programs, and after-sales service, ensuring that clients receive not just a machine, but a long-term cutting partner.

Conclusion

Fiber laser cutting technology has revolutionized the landscape of metal fabrication. With their high precision, energy efficiency, and ability to handle a variety of metals, fiber laser machines are the future of modern manufacturing. As industries continue to move toward smarter and more sustainable production methods, fiber lasers will undoubtedly play a central role in shaping that future.

SLTL Group stands at the forefront of this technological revolution, offering state-of-the-art fiber laser cutting solutions designed to meet the needs of today’s dynamic industries. With unmatched innovation, global expertise, and a strong focus on customer success, SLTL is the partner of choice for businesses ready to embrace the next era of manufacturing.

Ready to redefine your metal fabrication process?

Explore our advanced range of fiber laser cutting machines at www.sltl.com and take the first step toward smart, sustainable, and precision-driven manufacturing.