Introduction

Running a metal fabrication shop in the US? Then you know how crucial your equipment is to your bottom line. When it comes to industrial laser cutting machines, one wrong choice can lead to headaches, downtime, and lost profits. But don’t worry – I’ve got your back. This ultimate guide will walk you through exactly how to choose the perfect laser cutting machine for your operation. Ready? Let’s dive in!

Before you even start browsing machines, you need to fully understand your shop’s specific requirements. It’s like shopping for a truck – you wouldn’t buy a compact pickup if you’re hauling steel beams every day, right?

Understanding Your Metal Fabrication Needs

Production Volume

- Are you handling high-volume production runs or custom, small-batch projects?

- High production demands faster machines with greater automation.

- Small shops may prioritize flexibility over raw speed.

Types of Materials

- Are you cutting mild steel, stainless steel, aluminum, copper, brass, or a mix?

- Some machines handle reflective metals better (fiber lasers excel here).

Thickness of Metals

- Different machines have different cutting capacities.

- Thicker metals demand higher wattage and specialized optics.

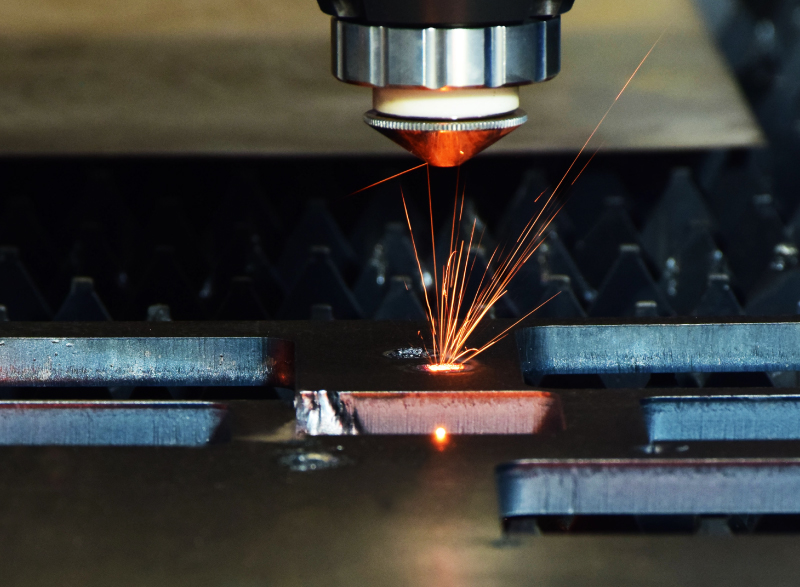

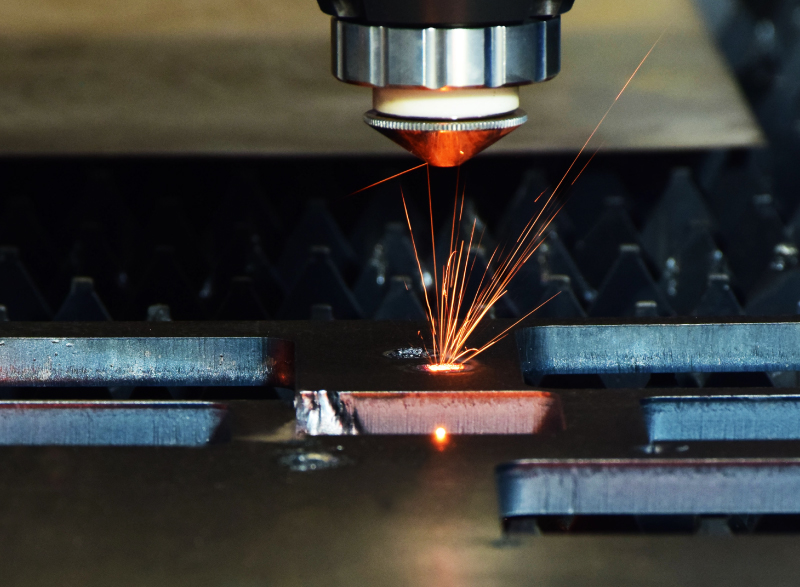

Types of Laser Cutting Machines

Now, let’s break down the main types of laser cutting technologies out there.

CO2 Laser Cutting Machines

- Great for non-metal materials (wood, plastics) but also cuts metals.

- Generally lower upfront cost.

- Higher maintenance (gas mixtures, optics).

Fiber Laser Cutting Machines

- The industry leader for metal cutting.

- Handles thin to thick metals effortlessly.

- Low maintenance, energy-efficient, faster speeds.

Crystal Laser Cutting Machines (YAG, YVO4)

- Older tech, rarely used today.

- High maintenance costs.

- Mostly obsolete for modern metal fabrication shops.

CO2 vs Fiber vs Crystal – Which One Suits You?

Choosing between these technologies can be overwhelming, so let’s simplify it:

Cutting Speed

- Fiber lasers dominate in speed, especially on thin materials.

- CO2 slows down as thickness increases.

Maintenance

- Fiber lasers have fewer moving parts and consumables.

- CO2 requires regular mirror and lens maintenance.

Operating Costs

- Fiber lasers consume less electricity.

- CO2 lasers require gases (like CO2 and nitrogen).

Application Suitability

- Fiber: Best for metals (including reflective ones like aluminum and copper).

- CO2: Decent for a mix of materials but not ideal for modern metal shops.

Key Features to Look for in an Industrial Laser Cutting Machine

Now that you know the types, let’s zoom in on key machine features.

Power Output

- Ranges from 1kW to 20kW+.

- Higher power = faster cutting + thicker capacity.

- But higher power also means higher upfront cost.

Cutting Bed Size

- Common sizes: 4×8 ft, 5×10 ft, 6×12 ft.

- Bigger beds handle larger sheets, reduce loading time.

Automation Capabilities

- Automated loading/unloading boosts productivity.

- Nesting software optimizes sheet usage.

Software Compatibility

- Look for user-friendly software.

- CAD/CAM integration is a huge plus.

Power Output and Its Impact

How Much Power Do You Really Need?

- Under 3kW: Suitable for thin sheet metal.

- 4-8kW: Versatile for most jobs.

- 10kW+: Heavy industrial cutting.

Power vs Material Type

- Stainless steel and aluminum often require higher power to avoid edge defects.

- Mild steel can be cut efficiently with lower wattage.

Cutting Bed Size Considerations

Small vs Large Bed Size

- Smaller beds = lower cost, space-saving.

- Larger beds = less material handling, more efficient for big projects.

Scalability Options

- Some machines allow future bed extensions.

- Modular design helps future-proof your investment.

Evaluating Machine Performance and Accuracy

Tolerance Levels

- Check the machine’s minimum tolerance specs.

- Precision matters for complex geometries.

Repeatability

- The ability to deliver consistent cuts every time is critical for production shops.

Edge Quality

- Smooth edges reduce secondary processing.

- Fiber lasers generally offer superior edge finishes.

Budget Considerations

Upfront Cost

- Expect to invest $300,000 to $1M+ depending on specs.

- Factor in installation and facility upgrades.

Operating Costs

- Power consumption, maintenance, and consumables.

- Fiber lasers typically have lower ongoing costs.

Long-Term ROI

- Calculate payback period based on production capacity and market demand.

- A higher upfront cost may lead to faster ROI if production is maximized.

Vendor Reputation and Support

Warranty and Service

- Look for at least a 2-year warranty.

- 24/7 service availability is a must for US operations.

Training and Installation Support

- On-site training ensures your team gets up to speed quickly.

- Remote diagnostics are a nice bonus.

Spare Parts Availability

- Domestic parts supply reduces downtime.

- Check vendor inventory and delivery timelines.

Regulatory Compliance and Safety Standards

OSHA Requirements

- Machines must comply with OSHA safety regulations.

- Proper shielding, ventilation, and operator protection are mandatory.

US Safety Certifications

- Look for UL, CE, or ANSI certifications.

- Compliance demonstrates machine quality and safety.

Future-Proofing Your Investment

Modular Upgrades

- Some machines allow for future upgrades as your shop grows.

Software Updates

- Cloud-based software ensures you stay current with new features.

Scalability

- Plan for future growth in cutting volume and material variety.

Case Studies: Success Stories from US Metal Fabricators

Real-World Examples

- A Texas-based fabrication shop upgraded to a 6kW fiber laser and doubled its capacity.

- A Midwest custom metal fabricator reduced waste by 30% with nesting software.

Business Growth Achieved

- Faster turnaround times.

- Improved customer satisfaction.

- Higher profit margins.

Conclusion

Choosing the right industrial laser cutting machine for your metal fabrication shop isn’t just a purchase — it’s a business decision that affects your future growth, profitability, and reputation. By carefully evaluating your needs, understanding your options, and working with a reliable vendor, you’ll make an investment that pays dividends for years to come. The US metal fabrication industry is fiercely competitive — but with the right machine, you’ll be ready to cut through the competition.

FAQs

1. What is the best laser cutting machine for small metal fabrication shops?

For small shops, a 3-6kW fiber laser with a 4×8 ft bed is often ideal for versatility and affordability.

2. How much does an industrial laser cutting machine cost in the US?

Expect to pay between $300,000 and $1M+, depending on power, features, and automation.

3. Can fiber lasers cut reflective metals like aluminum and copper?

Yes, fiber lasers excel at cutting reflective metals, unlike CO2 lasers.

4. How long does it take to train operators on a laser cutting machine?

With proper vendor training, most operators can be production-ready in 1-2 weeks.

5. What safety precautions are required for laser cutting in the US?

Ensure OSHA compliance with proper shielding, fume extraction, operator training, and certified equipment.