Introduction

Metal fabrication has undergone a dramatic transformation thanks to one incredible technology — laser cutting. If you’re a metal fabricator looking to up your game, choosing the right laser cutting machine can be a game-changer. But with so many options, features, and specs, how do you decide? That’s where this complete buyer’s guide comes in.

Why Laser Cutting Has Revolutionized Metal Fabrication

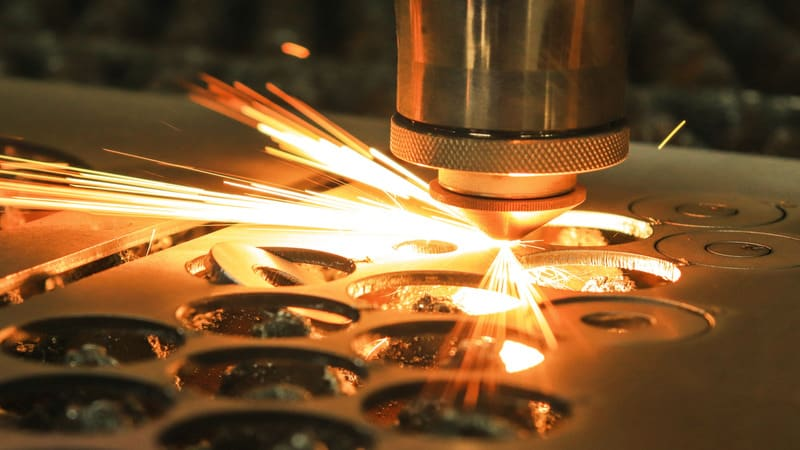

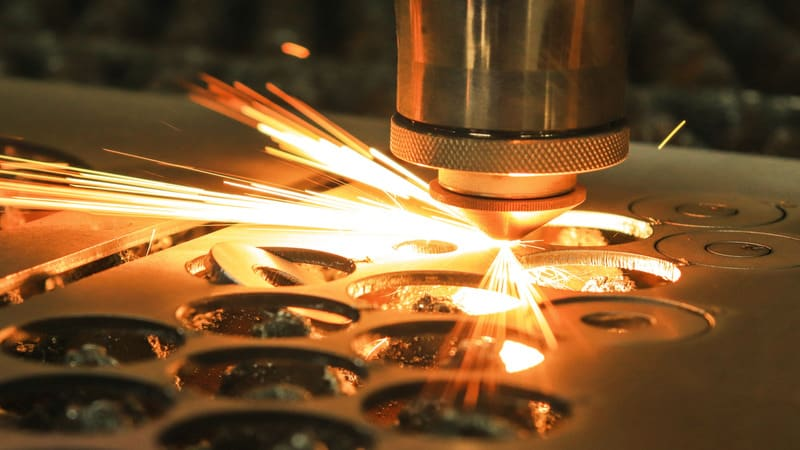

Remember when cutting metal was a slow, noisy, and messy job? Traditional cutting methods like mechanical sawing or plasma cutting worked, but they couldn’t match the precision, speed, or flexibility that lasers offer. With laser cutting, you get clean edges, complex shapes, and minimal material waste—all while operating with extreme accuracy. It’s no wonder laser cutting has become the go-to technology for metal fabricators worldwide.

Understanding Laser Cutting Machines

What is a Laser Cutting Machine?

At its core, a laser cutting machine uses a focused beam of light to melt, burn, or vaporize material. The beam, guided by computer-controlled systems, creates intricate cuts with pinpoint precision.

How Do Laser Cutting Machines Work?

Think of it like a magnifying glass focusing sunlight to burn paper. In laser cutting, lenses and mirrors concentrate the laser beam onto the metal’s surface. As the laser moves along the programmed path, it slices through the material cleanly and efficiently.

Major Types of Laser Cutting Machines

- Flatbed Laser Cutters: Ideal for sheet metal.

- Tube Laser Cutters: Specialized for pipes and cylindrical shapes.

- 3D Laser Cutters: Perfect for complex geometries and automotive parts.

- Hybrid Systems: Combine laser cutting with other machining processes for versatility.

Types of Lasers Used in Industrial Cutting

CO2 Laser Cutting Machines

CO2 lasers are gas lasers that produce infrared light. They’re versatile and work well on non-metal materials, but also cut metals like mild steel and stainless steel when equipped with the right power levels.

Fiber Laser Cutting Machines

Fiber lasers are the new gold standard for metal cutting. They offer higher efficiency, faster cutting speeds, lower maintenance, and better energy consumption. They shine especially on reflective materials like aluminum, copper, and brass.

Crystal Laser Cutting Machines (Nd:YAG, Nd:YVO)

Though less common today, crystal lasers offer high precision and are still used in specialized applications like medical device manufacturing or micro-cutting.

Key Components of a Laser Cutting Machine

Laser Source

The heart of the machine. This is where the laser beam is generated, whether it’s CO2, fiber, or crystal.

Cutting Head

Contains lenses and nozzles that focus the beam onto the material. Modern heads feature auto-focus capabilities for dynamic cutting.

CNC Controller

Acts as the brain of the machine, following programmed paths to guide the cutting head with incredible accuracy.

Assist Gas System

Uses gases like oxygen, nitrogen, or air to blow molten material away, prevent oxidation, and improve cut quality.

Major Applications in Metal Fabrication

Sheet Metal Cutting

Laser cutting dominates this area, producing components for industries like automotive, aerospace, and appliances.

Tube and Pipe Cutting

Specialized tube laser cutters handle round, square, or rectangular tubing, often used in structural frames and piping systems.

Precision Cutting for Electronics and Medical Components

Lasers excel at intricate, micro-level cutting essential for electronics, implants, and surgical tools.

Factors to Consider Before Buying

Type of Material and Thickness

Know what you’ll be cutting. Different machines handle varying materials and thicknesses better than others.

Cutting Speed and Precision

High-speed machines boost productivity, but accuracy is equally critical, especially for precision industries.

Power Requirements

Higher wattage machines (4kW to 15kW+) cut thicker materials but come with higher costs.

Machine Footprint and Space

Always measure your workshop space and consider machine dimensions, including auxiliary equipment.

Automation and Software Features

Features like auto-loading, nesting software, and remote monitoring can drastically improve productivity.

Maintenance and Service Availability

Choose manufacturers with strong service networks to minimize downtime and ensure fast repairs.

Comparing Top Laser Cutting Brands

TRUMPF

A German powerhouse, known for innovation and reliability. High upfront cost but unmatched precision.

Bystronic

Offers flexible solutions for various budgets while delivering excellent quality and automation.

Amada

Popular for its wide range of models catering to both small shops and large-scale manufacturers.

SLTL Group

An emerging leader known for cost-effective fiber laser solutions, robust customer support, and cutting-edge technology.

Others

Brands like Mazak, Han’s Laser, and Mitsubishi also offer quality machines depending on specific business needs.

Cost Breakdown of Laser Cutting Machines

Machine Cost

Prices range from $50,000 for entry-level models to $1 million+ for high-end automated systems.

Operating Cost

Includes electricity, assist gases, labor, software licenses, and consumables.

Maintenance Cost

Regular servicing, part replacements, and downtime affect overall expenses.

Hidden Costs

Training, installation, facility upgrades, and unforeseen repairs should be factored into your budget.

ROI and Long-Term Value

While laser cutting machines are a significant investment, their precision, speed, and low waste often pay off within a few years, especially when combined with growing demand for customized metal parts.

Common Mistakes to Avoid While Buying

- Ignoring power requirements

- Overestimating current and future production needs

- Skipping proper training for staff

- Failing to check manufacturer’s service and support quality

- Not calculating total cost of ownership

Future Trends in Laser Cutting Technology

- AI-powered cutting optimization

- Hybrid laser systems

- More energy-efficient lasers

- Predictive maintenance using IoT

- Increased use of automation and robotics

Conclusion

Choosing the right industrial laser cutting machine can be a daunting task, but with proper research and understanding, you can make a confident decision that boosts your metal fabrication business for years to come. Whether you’re just starting or scaling up, investing in the right laser cutter could be the smartest move you ever make.

FAQs

Q1: What is the lifespan of a laser cutting machine?

A high-quality laser cutting machine can last 10-15 years with proper maintenance.

Q2: Can fiber lasers cut all metals?

Yes, fiber lasers can cut a wide range of metals, including reflective materials like copper, brass, and aluminum.

Q3: How much power do I need for a laser cutter?

It depends on your material and thickness, but most industrial fabricators opt for machines in the 3kW to 15kW range.

Q4: Is laser cutting more expensive than plasma cutting?

The upfront cost is higher, but laser cutting offers better precision, lower running costs, and greater flexibility.

Q5: Do I need skilled operators for a laser cutting machine?

Yes, proper training is essential for safe operation and achieving optimal results, though automation reduces the skill barrier.